The Galician technology centre is leading the validation of a full-scale aeronautical demonstrator manufactured using advanced composite technologies.

The project has been selected as a finalist in the prestigious JEC 2026 international composite materials awards, in the Digital Manufacturing, AI & Data category.

O Porriño, 5th December 2025.– The AIMEN Technology Centre has presented the final results of CAELESTIS, a European project which, after 42 months of research and the participation of eleven national and international partners,has achieved significant advances in the manufacture of lighter, more efficient and sustainable aeronautical components.

Coordinated by AIMEN from May 2022 to October 2025, the project aimed to develop a hyperconnected simulation ecosystem and predictive technologies that would transform the design and production of aerospace structures. The initiative is part of the objectives of the European Green Deal, which aims for cleaner aviation with lower emissions by 2050.

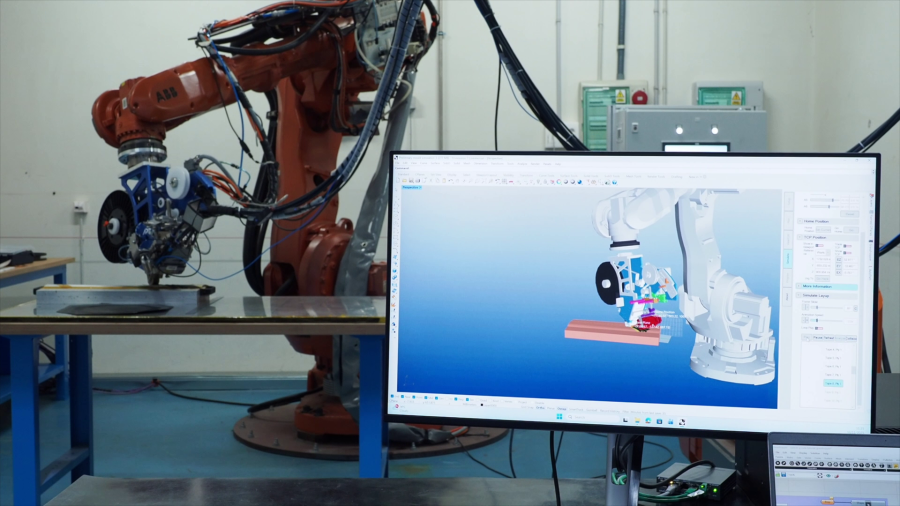

As a final validation of all the project developments, AIMEN has led the fine-tuning of the manufacture of the OGV (Outlet Guide Vane) composite demonstrator, a keycomponent in aeronautical turbines responsible for guiding airflow and contributing to engine efficiency, as well as providing structural support for the engine to the aircraft body. Its development combined automated dry carbon fibre lamination and RTM (resin transfer moulding) technologies for epoxy resin, processes in which a real-time quality control system was also integrated to prevent defects. This technological combination has made it possible to obtain more advanced components: the new OGVs offer an approximate 35% reduction in weight and up to an 80% reduction in manufacturing defects, helping to reduce fuel consumption and flight-related emissions.

International recognition for a European project led from Galicia

These results represent an important step towards the intelligent manufacture of aerospace composite structures, where automation, digitisation and advanced materials combine to drive a more sustainable industry without compromising performance or safety.

In recognition of its work, CAELESTIS has been selected as one of three finalists in the prestigious JEC 2026 (International Composites Show) international awards in the Digital Manufacturing, AI & Data category,one of the most important awards in the field of composites worldwide.

CAELESTIS is funded by the European Union and brings together partners specializing in aeronautics, advanced simulation, composites, automated manufacturing anddigital technologies. Its development demonstrates that Europe is moving towards a new generation of lighter, smarter and more environmentally friendly eronautical structures.

FEDER

FEDER