O Porriño, 5 de diciembre de 2022.- Las ventajas de los sensores de fibra óptica (FOS) sobre sus homólogos convencionales (termopares, galgas o extensómetros), en actividades de monitorización, están bien establecidas. Son más pequeños, más ligeros, más duraderos y pueden proporcionar un enorme número de puntos de medición a lo largo del sensor. Esto los convierte en la solución más atractiva para monitorizar, tanto instalaciones (equipos, tuberías, etc.), como componentes que requieren de sistemas poco invasivos. Así encontramos ejemplos de aplicación en segmentos industriales tan variados como son: transformación de energía (centrales eléctricas), ingeniería civil o sector aeroespacial. No obstante, la sensorización mediante fibra óptica presenta limitaciones para aplicaciones con temperaturas superiores a 450oC, ya que por encima de esa temperatura los sensores no son durables y es necesario recurrir a recubrimientos realizados con materiales muy costosos como puede ser el oro.

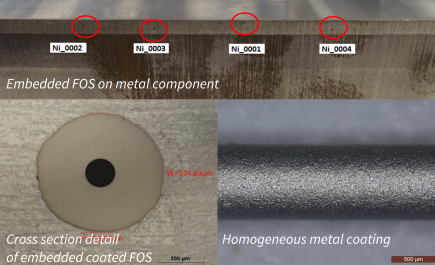

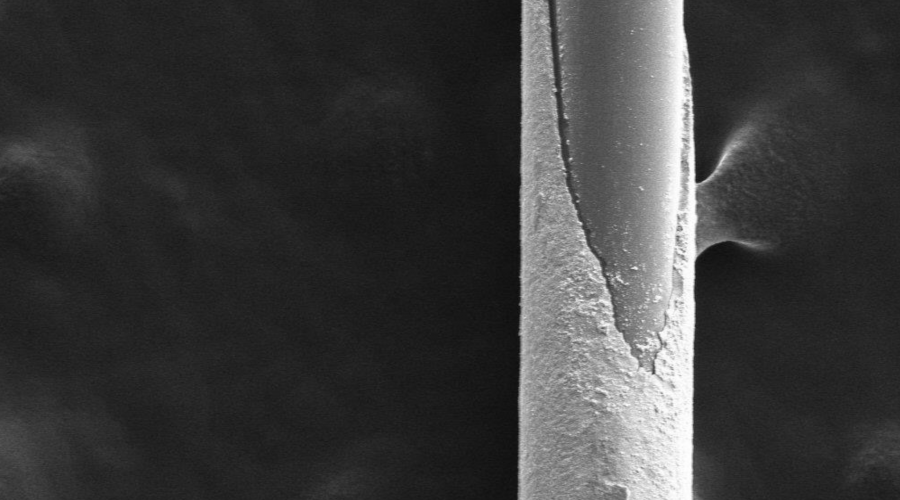

El centro tecnológico AIMEN ha desarrollado una nueva tecnología para generar un recubrimiento protector de níquel sobre sensores distribuidos y semi-distribuidos de fibra óptica, que permite a éstos operar en entornos con temperaturas superiores a 700ºC, y medir de forma simultánea temperatura y deformación. Además, con el nuevo proceso desarrollado por AIMEN se alcanzan espesores de recubrimiento de hasta 1.4 mm de espesor, varios órdenes de magnitud por encima de las soluciones disponibles comercialmente, proporcionando un recubrimiento más robusto y homogéneo. Por ello, los sensores recubiertos con esta tecnología también resisten procesos de embebido que conllevan alta temperatura, como la soldadura, para integrarlos en la propia estructura a monitorizar, o en componentes haciéndolos inteligentes. De tal modo que se pueden integrar en puntos de difícil acceso o en ambientes corrosivos evitando el uso de fijaciones o adhesivos que no aseguran su durabilidad a largo plazo.

Todas estas ventajas abren la puerta a nuevas aplicaciones en entornos exigentes, permitiendo medir múltiples puntos y varios parámetros de forma directa o indirecta: deformación, temperatura, vibración, fugas, presión, concentración de gas, carga, corrosión, etc.

Este nuevo recubrimiento ya ha sido validado en la industria por AIMEN en sectores como el energético, donde se han monitorizado distintos escenarios como el sobrecalentamiento de calderas en una planta de biomasa y en una planta de ciclo combinado, así como la deformación en un tanque de hormigón destinado a almacenar sales fundidas en una planta solar térmica. También ha sido testado en el sector naval, donde los sensores recubiertos de níquel se embebieron, mediante diferentes técnicas de soldadura, en el material antifricción de un componente de muy difícil acceso para controlar el estado del componente y detectar su degradación.

Además, el nuevo recubrimiento tiene potencial para otras aplicaciones en los sectores aeronáutico, químico, metalúrgico e incluso en sectores tan complejos tecnológicamente como pueden ser el geotérmico o el nuclear, debido a la estabilidad que proporciona a los FOS en condiciones adversas, a altas temperaturas.

El centro tecnológico AIMEN centra ahora sus esfuerzos en que esta innovadora tecnología para el recubrimiento de sensores de fibra óptica, que está pendiente de patente, sea transferida mediante un acuerdo con empresas fabricantes de fibra óptica y/o de los sensores, para lo que cuenta con el apoyo de la Xunta de Galicia en el marco del proyecto FRONTIER. Para ello se encuentra actualmente abierto un proceso de consultas y contactos con las empresas interesadas en la tecnología. Para más información contactar con: tania.grandal@aimen.es

El proyecto FRONTIER – Fibra óptica recubierta de metal de alta estabilidad para el monitoreo distribuido de infraestructura de alta temperatura, con código de expediente IN855A 2021/26 está cofinanciado por la Xunta de Galicia en el marco de la resolución del 9 de febrero de 2021 de la Axencia Galega de Innovación del 9 de febrero de 2021, Programa Ignicia Prueba de Concepto (DOG nº 32, de 19 de febrero de 2021).

FEDER

FEDER